|

||||||||||||

|

||||||||||||

|

||||||||||||

|

Cross-Disciplinary Plasma Science Laboratory |

||||||||||||

|

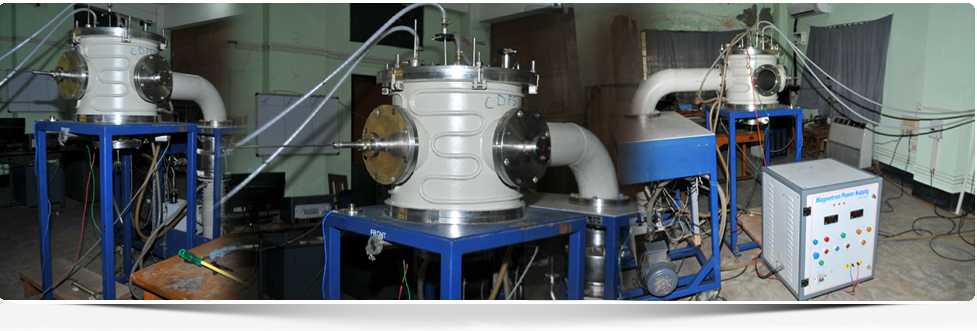

The CPPIPR CDPS Laboratory was set up originally with funding from North Eastern Council, Govt of India and the project tile was “Development of a Device for Plasma Assisted Hardening of Agricultural and Domestic Implements”. Later it was upgraded by funding received from DAE-BRNS with another project, “Development of duplex plasma based surface modification process involving dc pulsed magnetron sputtering and plasma nitriding with surface characterization”. The primary objectives of the laboratory are to exploit the industrial applicability of plasma technologies. The laboratory aims to develop technology for surface modifications of important industrial machinery parts, agricultural implements and cutting tools in cold plasma environme. Among several possibilities, one of the most promising combinations, for high-speed steels (HSS) is plasma nitriding of the substrate followed by physical vapour deposition (PVD) of a thin hard coating. For this purpose, the existing Plasma Nitriding reactor was upgraded to Duplex Processing Reactor with the assembling of a DC planar Magnetron for sputter coating of the pre-nitrided steels. Some significant results of this laboratory are hardening of SS304 and the background plasma chemistry studies of different active species of a nitriding plasma with Optical Emission Spectroscopy which are given in the references below. Presently we are taking up the following work on plasma processing. | ||||||||||||

| » | TiN (Titanium nitride) coating on plasma nitrided high speed steel(HSS). | |||||||||||

| » | AlN (Aluminium nitride) coating on plasma nitrided high speed steel(HSS) | in collaboration with the FCIPT, IPR. Our observations are as followings: |

||||||||||

| » | The surface hardness of plasma nitrided AISI M2 steel increased by a factor of 4 (845HV0.1). |

| » | Depth of diffusion zone was 500 μm |

| » | Surface roughness increases after TiN deposition on plasma nitrided samples. |

| » | TiN film deposited on PN samples shows Cauliflower or Shell type surface appearance as compared to untreated TiN coated sample. |

| » | Compared to only TiN coated surface , the hardness of PN+TiN coated samples are high which indicates well Growth of TiN films on plasma nitrided surface. |

| » | For higher Nitrogen flow rate the micro-hardness of duplex coated samples are larger than only TiN coated samples. |

|

Recently, we have also taken up the surface modification of polymers for use in biomedical application in CDPS. Here, few polymeric hydrogel substrates are being treated with suitable plasmagen gases to study the effects of surface treatment. An increase in hydrpohilicity and surface roughness are expected from the plasma treatment. Polymers being sensitive to high temperatures, they are generally surface treated with atmospheric plasma. In our lab we modified the magnetron sputtering target by using a grid with the polymer target to see whether the desired surface modification could be achieved. The SEM showed visible signs of etching in the morphology of the commercial polymer treated with Argon sputtering. We have also synthesized some polymer hydrogels which have known biomedical applications and toughened by a benign chemical cross linking process so that they remain non-toxic and suitable for biomedical applications. These samples are being treated in both our magnetron sputtering plasma and Atmospheric and RF plasmas to compare the relative differences in surface properties such as etching pattern, (from SEM) and hydrophilicity (by contact angle measurement). Research Scholars obtaining PhD degree from this laboratory are: 1. Dr. Manash Kumar Sarma 2. Dr. Arindam Phukan 3. Dr. Partha Saikia References:

Part II: Plasma Surface Modification of Toughened Polymeric Hydrogels for Biomedical Applications : Surface modification of polymers for biomedical applications has received attention in the market and industry as a convenient solution to the huge demand for biomedical devices, especially in view of a large section of ageing population in countries throughout the world. It is an attractive option for designing biomaterials because host–guest responses in biomedical implants are mostly surface processes. At the same time a polymeric implant having the necessary mechanical strength or bulk properties can be used. Over the past decade, one of the most active areas of polymeric biomaterials research involved cartilage repair. This activity has resulted because cartilage defects cannot adequately heal themselves. As a result, millions of people require treatment to repair damaged cartilage. Biomaterials for cartilage repair often involve polymeric hydrogels. As hydrogels in their unmodified form suffer from adequate mechanical strength, hence there is a need to toughen these with adequate biofriendly processes. Two important criteria for biomaterial implants are: a) They should be safe (non-toxic), (b) biomaterial should not elicit an allergic response within the body. As plasma treated materials are made free of solvents and surface (Leachable chemicals), hence they are largely non-toxic. By treating with plasma, the biomaterial can be made more responsive for interaction with cellular materials and body fluids. This promotes better adhesion (Surface to surface contact) of the biomaterial with the body and reduces the chances of an allergic response or rejection of the implanted biomaterial by the body. By increasing porosity, the surface is made more responsive towards cell growth and proliferation, which makes it more biocompatible. The literatures show plasma sputtering as the process suitable for doing this. RF plasma sputtering is found to be one of the most adequate and advanced technique as it produces (i) low temperature plasma, which is favorable to sputter soft material like polymer (ii) large volume stable plasma, which can be utilized to treat larger sized samples and (iii) it can be utilize to treat non conducting material as generally, the biomaterial are no-conducting material. It is worth mentioning that the biomaterials in use in the India are mostly imported and therefore there is a need for the indigenous growth in R & D for this area. Visualizing the importance, Works on the surface modification of toughen polymeric films is being initiated at CPP-IPR. In our lab, a few polymeric hydrogel substrates are being treated with suitable plasmagen gas to study the effects of surface treatment. An increase in hydrpohilicity and surface roughness are expected from the plasma treatment.Following works have been carried out so far

A) In-house synthesis of the toughened polymeric hydrogels: Polyvinyl alcohol (PVA), was made into a solution of varying percentages with which silicate solutions of varying percentages were mixed together in magnetic stirrer. B) Plasma surface modification of the toughened polymer hydrogels by magnetron sputtering: Synthesised PVA were treated in Magnetron Plasma device by replacing the target with a stainless steel grid. The SEM showed visible signs of etching in the morphology of the toughened polymer hydrogels treated with Ar sputtering. C) The prepared samples were subjected to atmospheric DBD treatment at FCIPT. There are distinct changes in the surface morphology compared to the sputtering experiments. D) The toughened polymer samples were subjected to a RF treatment under a operating voltage of 35W. However, due to instrument limitations at our lab and at FCIPT, this study has not been completed. E) FTIR study of the sputter treated and DBD treated samples: The FTIR of the DBD treated samples showed an increase in percentage of the hydroxy groups in the DBD treated samples. There wasn't any significant increase in the percentage of hydroxy groups in the sputter treated samples. a) Treatment of polymers and toughned hydrogels with RF plasma. b) Investigation of the surface modified materials for biomedical applications. | ||||||||||||

| Former research workers of this laboratory are: |

||||||||||||

|

Dr. T. Kotoky, PDF Email: tkotoky@gmail.com |

|||||||||||

|

Dr. N.K. Neog, Scientific Officer – E Email: nirod@cppipr.res.in |

|||||||||||

|

Quick Links |

|||||

| Home | Profile | Gallery | RTI | Webmail | Reach Us |